IoT Solution Optimizes Ease of Use & Functionality for Commercial Grade Water Jet Cleaning System

DYNAJET, of Nürtingen, Germany, approached HED for electronics that would enable new user functionality in their premium class ultrahigh-pressure cleaner. DYNAJET manufacturers powerful and long-lasting water jetting systems and accessories up to 3,000 bar (43,500 PSI) for professional applications in a variety of industries including construction, renovation, service providers, local authorities, industry, shipyards and forestry.

The challenge was to develop a solution that would increase equipment usability, up-time, operator safety and serviceability. DYNAJET needed a control solution that delivered market-leading technology and application engineering support that provided technological thought leadership.

DYNAJET UHP 220

HED delivered an innovative solution that integrates the CL-709 4.3” LCD display, CL-305 power control module, CL-449 IO module and the CANect® CL-T04 Wi-Fi module. The CL-709 4.3” LCD display provides full-system control and a wealth of information via its user interface.

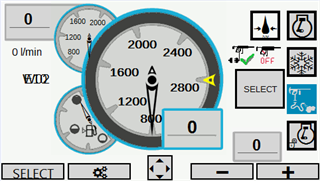

UHP 220: Display Graphical User Interface

The display provides fine pressure control of the nozzle, engine diagnostics for the Volvo power plant and feedback for system interlocks and faults. The CL-709 provides a comprehensive view of all equipment functions and provides service personnel and operators with complete functional continuity.

The CL-305 is an output module that can simultaneously distribute 10A of current to each of the 8 outputs using solid state technology. The module has internal diagnostics that provide output current, diagnostic feedback and self-protection capabilities.

HED CL-305 and CL-449 IO Modules

The CL-449 is a cost-effective and highly configurable IO module that is used by DYNAJET to add additional inputs to the pressure system. It provides pressure, temperature and tank level feedback to the control system. The CL-449 allowed DYNAJET to expand sensor coverage on the pressure system to increase operator convenience.

CANect® CL-T04 Wi-Fi Module

The CANect® CL-T04 Wi-Fi module connects the pressure washer wirelessly to operators, owners and service personnel. It leverages the latest technology in embedded connectivity and internet-of-things (IoT). The CANect® Wi-Fi device can even store and present digital service literature and media.

DYNAJET – Web Application

DYNAJET utilized the CL-T04 to allow operators to view VOLVO’s Tier 4 Final engine diagnostics and resolve equipment metrics/diagnostics on the pressure cleaner. This was achieved by developing a rich user-interface via a web application on the Wi-Fi module. The web app on this ultrahigh-pressure pump enables cross-platform compatibility on PCs and mobile devices.

Equipment-To-Device Communication

The CL-T04 Wi-Fi module goes beyond providing diagnostics and operator feedback. It is used to program and calibrate the equipment during assembly in the factory. For instance, DYNAJET can remotely troubleshoot and service field-located rental fleet units from their headquarters via a GSM hotspot, and remotely reconfigure system calibrations based on the equipment configuration. This remote access functionality is called CANect® reflector, which provides remote viewing and control of the web application from anywhere in the world by connecting the CL-TO4 Wi-Fi module to a GSM hotspot.

Like a smart housing thermostat, the UHP 220 can connect to your mobile device and provide configuration, control and operating alerts. However, the distinction lies within details of the application. The average smart thermostat isn’t connected to a 311 cubic inch diesel engine that pressurizes water to 40,000 PSI.

Equipment-To-Infrastructure Communication

DYNAJET has implemented many new control features in this product and plans to deploy many more in the future. For example, this device can automate maintenance scheduling on-device. No need to transmit and post-process data in the cloud; process data locally on the device. Ultimately, the CANect® CL-T04 is a powerful, connected device that provides valuable functionality to the UHP220. It allows DYNAJET to monitor, control, troubleshoot and reprogram their system from any internet enabled device, all with proper security to safeguard operation.

In conclusion, DYNAJET was able to utilize HED control technology to deliver on several application challenges:

- Increase equipment usability

- Increase vehicle up-time

- Enhance operator safety

- Improve ease of serviceability

These deliverables improve the operator experience and reduce total cost of ownership, all while meeting safety requirements.

Carsten Funk, Technical Director – DYNAJET states,

“We were searching for a robust and state of the art mobile controller. Our machinery has to sustain harsh conditions on job sites. The requirements include safe operation, connectivity and programming tools that are easy to handle. We were right away impressed with the level of motivation that HED was showing. Our approach to have big portions of the programming done outside of our company required a lot of trust. The people of HED on all levels showed that this trust was well invested. Collaboration over the span of 6 time zones and dealing with cultural and language differences was easier than expected. Some people at HED became our colleagues and even friends throughout the project. We managed to endeavor steep learnings curves together and to find solutions that fit our market and that work in Europe. I recommend HED as a partner with competence and knowledgeable people – who are willing to go the extra mile even if it means to be in the office at 2am to bridge the time difference gap.”

For more information on how HED technology can help you optimize your vehicle’s performance, please contact us.