Data Visualization Tools

Provide the IoT experience and brand that your customers expect using our CANect® Telematics data visualization tools. Easily translate custom, raw data sets into powerful data insights and real-time visual cues. Whether you're next to the machine or halfway around the world, CANect visualizations will allow you to make an impact effortlessly.

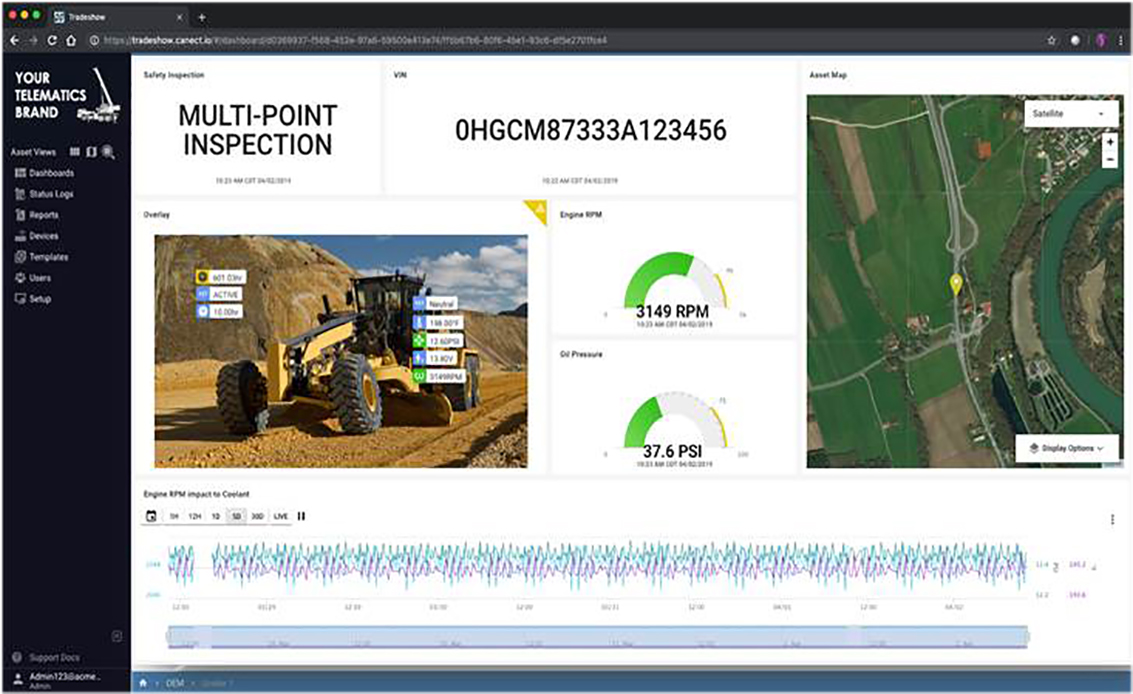

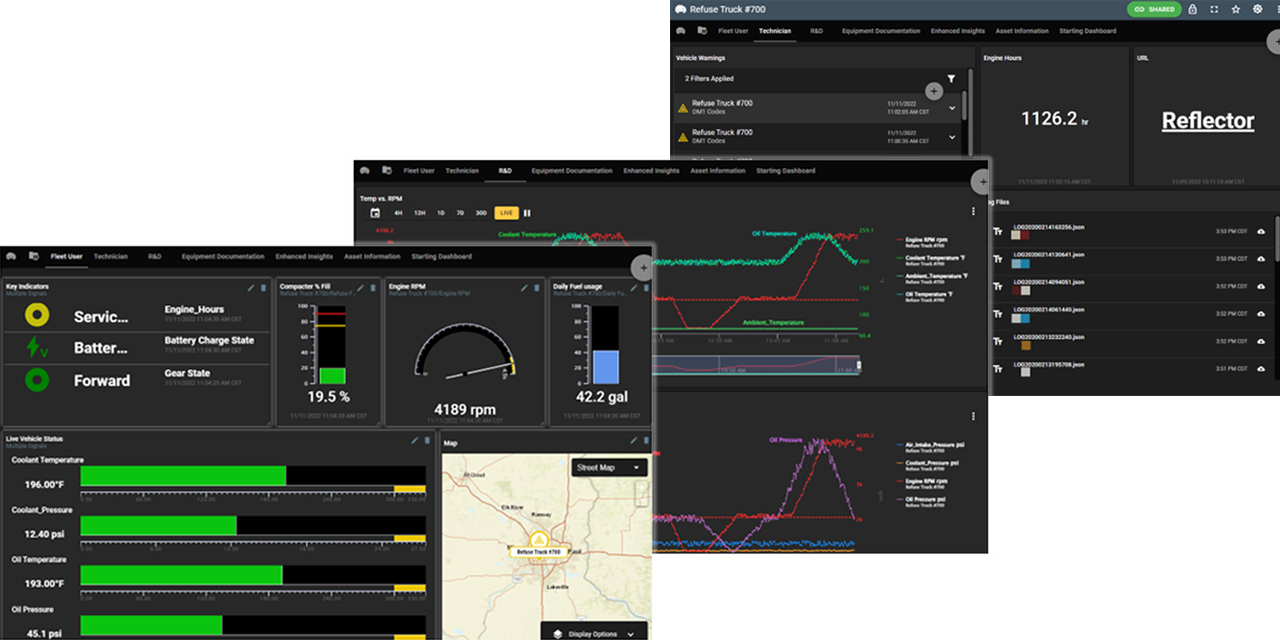

Customizable Fleet Management Solution | CANect PortalTM

Overcome the challenge of getting critical information to the right people, anywhere, at any time. Present data clearly and concisely using persona-driven dashboards, color-coded status icons, and real-time alerts. Imagine, maintenance technicians seamlessly access data trends and prognostics, while fleet managers effortlessly monitor operator performance and machine utilization. This critical data helps OEMs and their customers identify efficiencies that impact ROI.

Cloud based, completely secure storage and backup

Ensure data integrity in the increasingly complex world of data security. HED eliminates the risk of instability through data backups and redundancy protections.

CANect Portal features:

- Completely Configurable - Leverage custom data from the module to create data transformations, insights and alerts

- Secure Data Access - Create hierarchical user credentials and permission sets

- Two-Way Programming - Update vehicles from anywhere in the world using Over-The-Air-Programming (OTAP)

- Customized Notifications - Deliver condition-based alerts automatically via SMS or email

- Geofencing and Curfews - Configure rules for specific vehicle assets or an entire fleet

- Post-Processing & Analysis - Enable data-led strategies with exports and APIs to navigate big data

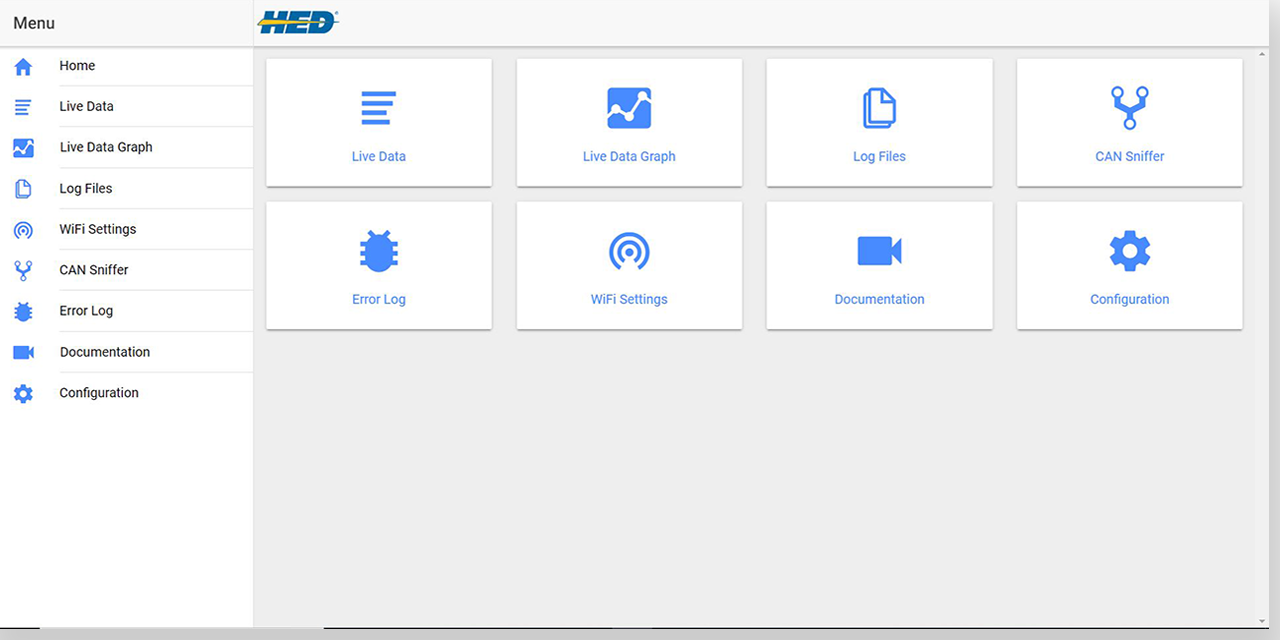

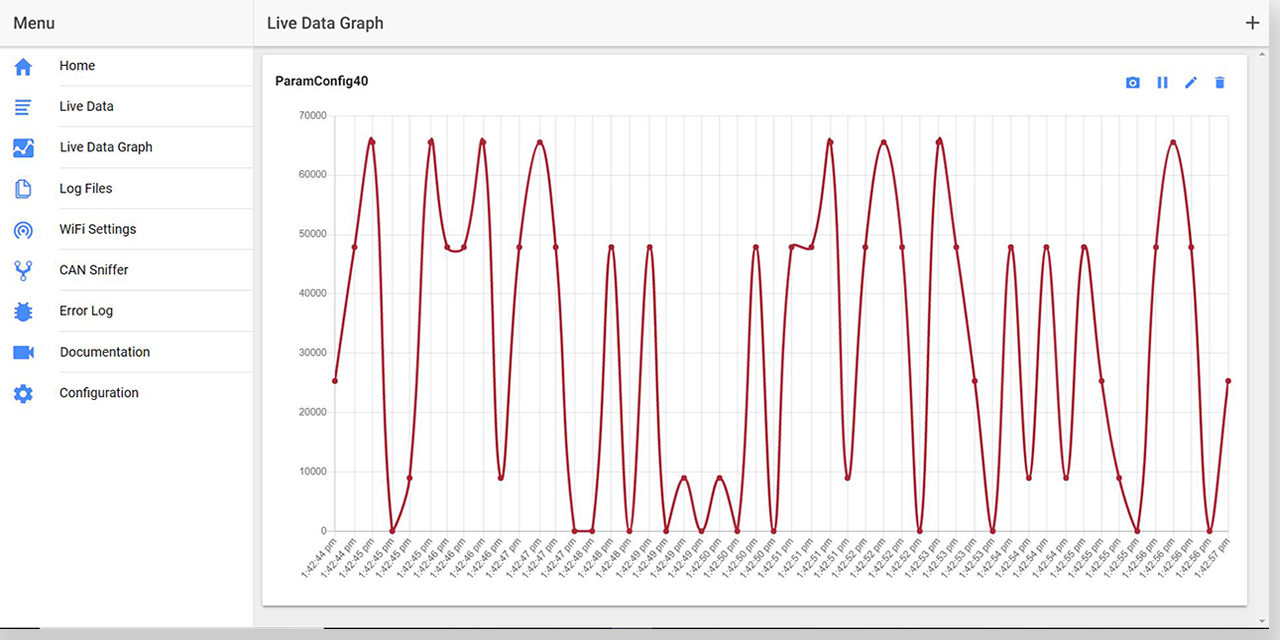

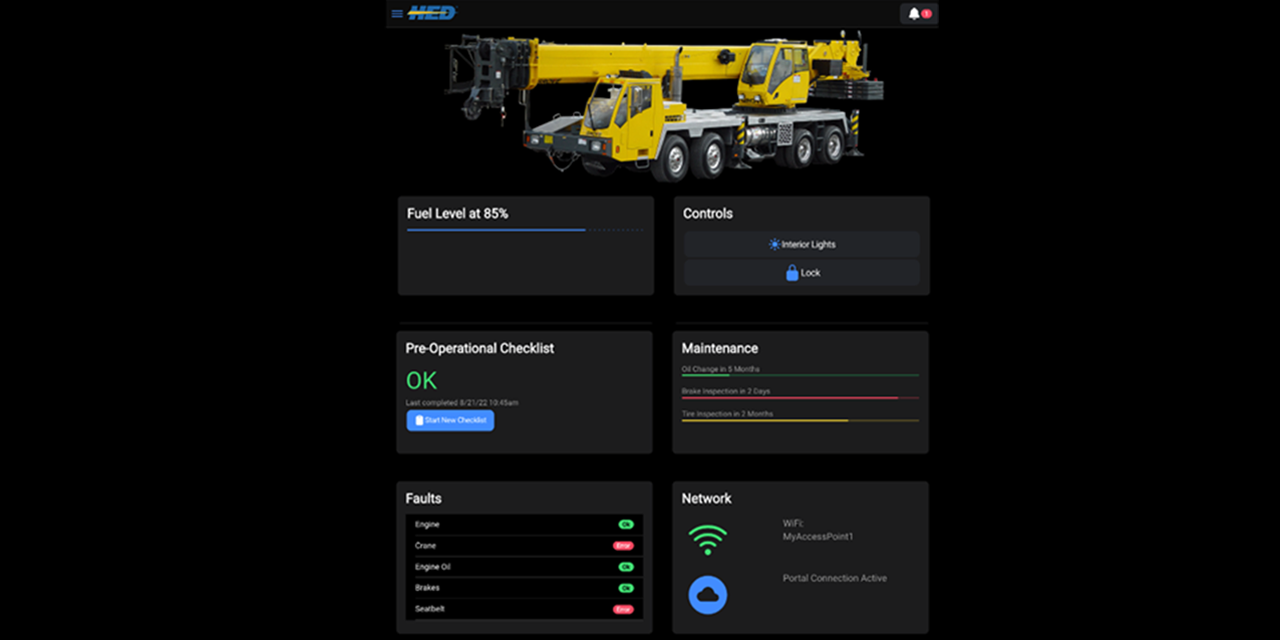

On-Location Equipment Access & Control | CANect ViewTM

Interact with Vehicle Control Systems Wirelessly

Collect, display and even control equipment in real-time - without the lag of round-trip IoT communication. CANect modules are pre-loaded with our turnkey application, which auto-syncs to data insights that have been configured on your existing module.

Access Vehicle Data On-Site from Any Device

- Real-Time Equipment Health - Build your own real-time vehicle health dashboards using a rich Graphical User Interface (GUI)

- Diagnostics & Historical Data - Log & export all configured parameters

- Interactive Troubleshooting - Immediate feedback from control and telematics systems as troubleshooting takes place

- Remote Interaction - React to external environments quicker by controlling equipment functions such as lighting, HVAC, door locks, etc. from afar

- Resource Access - Improve operational efficiency with on-module resources such as service videos and equipment manuals

- OTAP - Wireless over-the-air programming and configuration

Build Your Own Experience

Create your own CANect ViewTM application using standard web development languages (python, php, nodejs) to support unique workflows and experiences.

- Display Mirroring or BYOD

- Revenue Opportunity Capture

- Remote Equipment Control

Remote Equipment Access & Control | CANect ReflectorTM | (View™ Add-On)

Access Vehicle Data from Anywhere in the World

CANect Reflector allows users to view and communicate directly with the CANect® module on vehicles from any internet-enabled mobile device or PC world-wide. This provides users with the capacity to view and troubleshoot real-time equipment functionality as if you are standing next to the equipment. Reflector is ideal for:

- Remote technical support

- Real-time monitoring

- Downloading of detailed log files

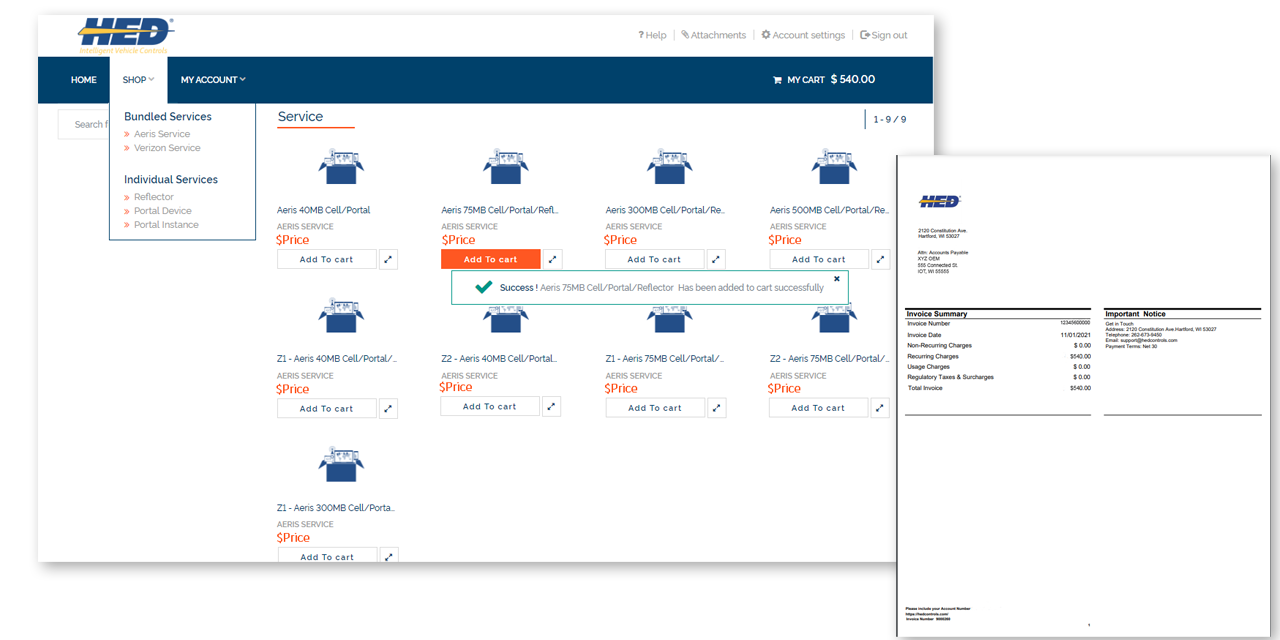

Simplify Your Solution with CANect Marketplace

Enablement through your organization is the key to a successful IoT Solution. Simplify the process with the CANect® Marketplace. This self-serve subscription platform allows OEM's to manage recurring subscriptions for cellular and cloud services.

Featured Products & Services

Back-Office Portal | CANect®

- Flexibility to deliver the user-experience your customers expect

- Tailor expected experiences to each layer of engagement

- Graphs & research data for engineers

- KPIs for fleet users

- Repair and equipment details for technicians

Need something else? CANect Portal is fully customizable to meet your needs

New Telematics Features

Designed To Make Your Life Easier

- Upload files to back-office portal - logs, photos, checklists and more

- Import your CAN database directly into our do-it-yourself Composer configuration tool

- Easily deploy software to multiple regions/carriers

Wireless Equipment Service Tool | View®

- Improve productivity - Unique application deployment (point of sale, custom checklists)

- Reduce repair costs & downtime - Remote troubleshooting & metric visibility

- Enhanced self-serve experience - Keep it simple for end users with pre-built insight

Get Telematics Application Ideas

Learn what other OEMs are doing to differentiate their offering.

Need Engineering Support?

Our engineering teams are readily available to support your project.